| 来源 | 天然沸石 |

|---|---|

| 类别 | 斜发沸石 |

| 产地/厂商 | 河南 |

| 包装规格 | 25kg/袋 |

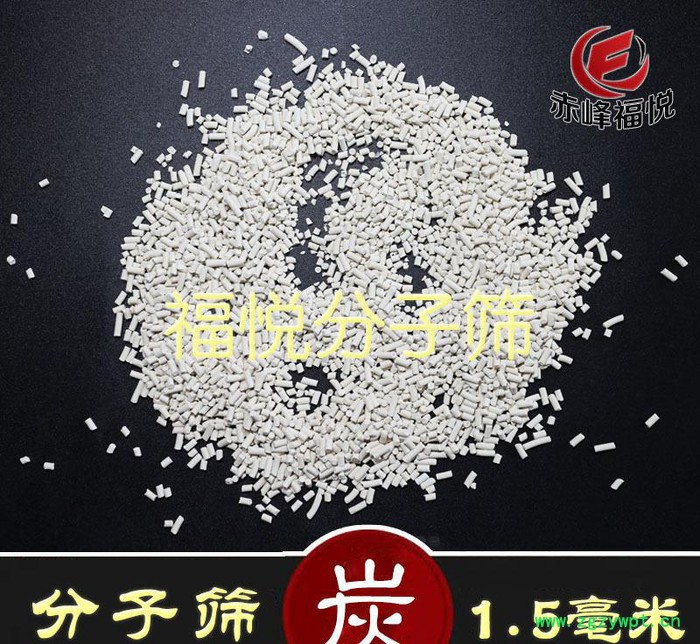

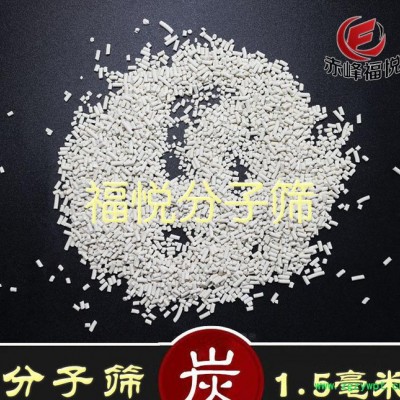

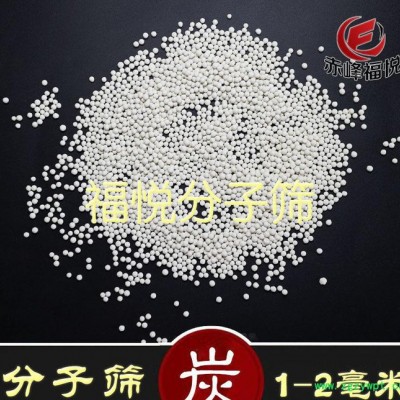

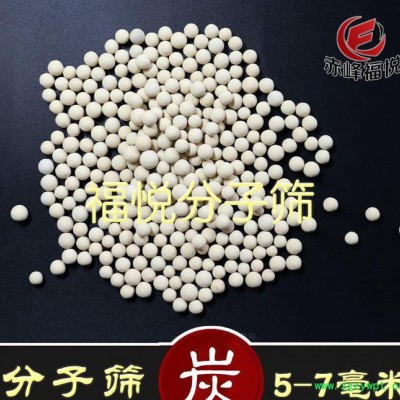

| 颗粒度 | 1-2 2-4 3-5 4-6(mm) |

| 堆积密度 | 0.62(g/ml) |

| 有效物质含量 | 98(%) |

| 水份 | 1.3(%) |

| 品牌 | 赤峰福悦 |

| 型号 | 3A |

赤峰福悦一种人工合成且对水分子有较强吸附性的干燥剂产品。分子筛的孔径大小可以通过加工工艺的不同来控制,除了吸附水汽,它还可以吸附其他气体。分子筛具有均匀的微孔结构,它的孔穴直径大小均匀,这些孔穴能把比其直径小的分子吸附到孔腔的内部,并对极性分子和不饱和分子具有优先吸附能力,因而能把极性程度不同,饱和程度的不同,分子大小不同及沸点不同的分子分离开来,即具有“筛分”分子的作用,故称分子筛。由于分子筛具有吸附能力高,热稳定性强等其它吸附剂所没有的优点,使得分子筛获得广泛的应用。在230℃以上的高温情况下,仍能很好的容纳水分子。

指标 | 单位 | 球状 | 条状 | ||

直径 | 目 | 2-3 | 3-5 | 2-3 | 3-5 |

静态水吸附 | ≥%wt | 21.5 | 21.5 | 20.5 | 20.5 |

吸附甲醇量 | ≥mg/g | 150 | 150 | 140 | 140 |

堆积密度 | ≥g/cm | 0.66 | 0.66 | 0.64 | 0.64 |

抗压强度 | ≥N | 60 | 80 | 40 | 70 |

磨耗率 | ≤%wt | 0.1 | 0.1 | 0.2 | 0.2 |

残余含水量 | ≤%wt | 1.5 | 1.5 | 1.5 | 1.5 |

3A型分子筛:主要用于石油裂解气、烯烃、炼气厂、油田气的干燥,是化工、医药、中空玻璃等工业用干燥剂。

4A型分子筛:主要用于天然气以及各种化工气体和液体、冷冻剂、药品、电子材料以及易变物质的干燥、氩气纯化、甲烷、乙烷丙烷的分离。

5A型分子筛:5A分子筛的大比表面积和极性吸附达到对水和残余氨的深度吸附。分解后的氮氢混合气进入干燥器,除去残余水分及其他杂质。纯化装置采用双吸附塔流程,一台吸附干燥氨分解气,另一台在加热状态下(一般在300-350℃)解吸出其中的水分及残余氨,从而达到再生的目的。

中空玻璃专用分子筛系列:分子筛可以同时吸附中空玻璃中的水分和残留有机物,使中空玻璃即使在很低温度下仍然保持光洁透明,充分降低中空玻璃因为季节和昼夜温差变化所承受的强大内外压力差,彻底解决普通中空玻璃干燥剂易使普通中空玻璃膨胀或收缩导致的扭曲破碎问题,充分延长中空玻璃的使用寿命。

3A分子筛的孔径是3A,主要用于吸附水,不吸附直径大于3Å的任何分子,根据工业上的应用特点,分子筛具有快吸附速度、再生次数、抗碎强度及抗污染能力,提高了分子筛的利用效率并延长了分子筛的使用寿命,是石油、化工行业中气液相深度干燥、精炼、聚合所必需的干燥剂。

4A分子筛的孔径为4A,吸附水,甲醇、乙醇、硫化氢、二氧化硫、二氧化碳、乙烯、丙烯,不吸附直径大于4A的任何分子(包括丙烷),对水的选择吸附性能高于任何其他分子,是工业上用量最大的分子筛品种之一。

5A分子筛的孔径为5A,能吸附小于该孔径的任何分子,主要应用于正异构烃分离、变压吸附分离及水和二氧化碳的共吸附,基于5A分子筛的工业应用特点,我们生产的5A分子筛选择吸附高、吸附速度快、特别适用于变压吸附,可适应各种大小的制氧、制氢、制二氧化碳等气体变压吸附装置,是变压吸附行业中的最佳选择。

X型:硅铝酸盐的晶体结构不同(硅铝比大小不同样),形成孔径为9―10A的分子筛晶体,称为13X(又称钠X型)分子筛;用Ca2+交换13X分子筛中的Na+,形成孔径为9A的分子筛晶体,称为10X(又称钙X型)分子筛。

Y型:Y型分子筛具备X型分子筛烃似的晶体构造,但化学组成不同(硅铝比拟大)通常用于催化范畴。

赤峰市福悦活性炭厂

地 址:内蒙古赤峰宁城县天义镇富家窝铺村(原糖厂南侧)

经 理:李果

手 机:15047259045

Q Q:3271344781

邮 箱:3271344781@qq.com

网 址:https://shop1438707253312.

Product introduction

A kind of artificial synthesis and water molecules have a strong adsorption of desiccant products. The pore size of molecular sieve can be controlled by different processing technology, in addition to adsorbing water vapor, it can also adsorb other gases. Molecular sieve has a uniform microporous structure, cavity diameter of its uniform, these holes can than the diameter of small molecules adsorbed to the internal cavity, and has the priority on the adsorption capacity of polar molecules and unsaturated molecules, which can make different degrees of saturation degree, different from different molecular size molecular separation and the boiling point of different, that is "sieving" molecules, called molecular sieve. Molecular sieve has the advantages of high adsorption capacity, high thermal stability, and so on, so that the molecular sieve is widely used. In the high temperature of 230 degrees Celsius, still can be very good to hold water molecules.

The product uses

3A type molecular sieve: mainly used in oil gas, oil gas plant, olefins, refining and drying, desiccant is chemical and medicine, hollow glass industry etc..

4A type molecular sieve: mainly used in natural gas and various chemical gases and liquids, refrigerants, medicine, electronic materials and volatile substances, dry argon purification, methane, ethane and propane separation.

: 5A zeolite 5A molecular sieve with large surface area and polar adsorption to a depth of adsorption of water and residual ammonia. Decomposition of nitrogen and hydrogen into the dryer, removal of residual water and other impurities. The purification device adopts double tower adsorption process, a drying ammonia gas, another in a heated state (300-350 C) solution to suction out the water and residual ammonia, so as to achieve the purpose of recycling.

Hollow glass molecular sieve series: molecular sieve can be simultaneously adsorbed hollow glass of water and organic residues, the hollow glass even at very low temperature keeps clear and transparent, fully reduce hollow glass because of changes in seasonal and diurnal temperature difference under strong pressure difference between the inside and outside, completely solve the ordinary insulating glass desiccant to ordinary hollow glass expansion or contraction leads to distortions breaking, extend the service life of the hollow glass.

Molecular sieve classification

Pore 3A zeolite is 3A, mainly used for the adsorption of water, adsorption of any molecule a diameter of more than 3, according to the application characteristics of the industry, molecular sieve has quick adsorption rate, regeneration times, crushing strength and anti pollution ability, improve the utilization efficiency of molecular sieve and prolong the service life of the molecular sieve. Is the gas and liquid petroleum and chemical industry, refining, drying phase depth required for polymerization of desiccant.

Pore 4A molecular sieve was 4A, adsorption of water, methanol, ethanol, hydrogen sulfide, sulfur dioxide, carbon dioxide, ethylene, propylene, adsorption of any molecular diameter is more than 4A (including propane), the selective adsorption performance of water molecules is higher than any other industry, the large amount of molecular sieve of varieties.

Pore 5A molecular sieve adsorption is 5A, smaller than any of the molecular aperture, CO adsorption separation, mainly using Yu Zheng adsorption separation of isomeric hydrocarbon and water and carbon dioxide, industrial application of 5A based on molecular sieves, selective adsorption, high adsorption speed, especially suitable for PSA 5A molecular sieve production we that can adapt to various sizes of oxygen, hydrogen, carbon dioxide and other gases pressure swing adsorption device is the best choice of PSA in the industry.

Type X: crystal structure of aluminosilicate (different Si / Al ratio is not the same size), the formation of the aperture is 9 10A molecular sieve crystal called 13X (also known as sodium X type molecular sieve); Ca2+ is used to exchange the 13X molecular sieve Na+, forming a pore size of 9A molecular sieve crystals, called 10X (also called calcium X type molecular sieve).

Y type: Y type molecular sieve crystal structure with X type molecular sieve like hydrocarbon, but the chemical composition (silicon aluminum analogy) commonly used in catalytic field.

Contact information

Chifeng City, Fu Yue activated carbon plant

Address: Inner Mongolia Chifeng Ningcheng county rich Wo Pu Cun (sugar factory in the South)

Manager: Li Guo

Cell phone: 15047259045

Q:3271344781 Q

Mailbox: 3271344781@qq.com

URL: https://shop1438707253312.

赤峰市福悦活性炭厂

地 址:内蒙古赤峰宁城县天义镇富家窝铺村(原糖厂南侧)

经 理:李果

手 机:15047259045

Q Q:3271344781

邮 箱:3271344781@qq.com

网 址:https://shop1438707253312.